You don’t need to look at the

artist page of Steingraeber Piano for too long before you start to realize that their pianos are highly sought after and prized by world renown pianists. It begs the question, what are they experiencing that compels them to perform on their pianos? What goes into a Steingraeber piano that sets it above others? I had the wonderful opportunity of sitting down with Udo Steingraeber at this last NAMM show in California. It was one of those unplanned, unscheduled talks which revealed much about this 6th generation piano maker and his company.

Glen Barkman: At what age did you get into the business of piano making?

Udo Steingraeber: I started at age 15 working in my father’s factory. After graduating high school, I went to university to study, Law, Arts and Theatre. Unfortunately, my father passed away when I was 24 and so I assumed responsibility of the company.

GB: When I think of myself at age 24, I can’t imagine taking the reigns of a company at such an early age. What were your thoughts back then?

US: Thankfully I had already worked in the factory for nearly a decade and I was familiar with day to day operations. We also had the legacy and history to draw upon and I was also still surrounded by master technicians who continued to work for the company. We carried on.

GB: Speaking of history, this year you celebrate your 200th anniversary! Congratulations! There are very few companies in the world with your historic background. And so, drawing upon this legacy, and looking forward to the future, what was your vision?

US: I realized that the world doesn’t need another “good” piano. It needs pianos that are both excellent and different. From its inception, Steingraeber has always had close connections with artists. One of the pianos we house at our facility is Liszt’s personal Steingraeber grand piano. And I have to say that there is a lot to be learned from historic pianos. It has been said that piano design was largely consolidated by the beginning of the 20th century. These modern designers spurned the efforts of the piano makers from the 18th and 19th centuries and yet ironically, that’s when the majority of Classical composers lived. It seemed that the modern piano should be faster, louder, thicker, “more”. But Edward and George Steingraeber, my predecessors didn’t follow these trends. The Steingraeber legacy is about giving the artists what they need to fully express their voice. Our desire is to create pianos that contain excellence in these 4 elements: construction, sound color, polyphony and sound transparency.

GB: Transparency ~ what does that mean to you?

US: I mean that individual notes can always be heard. With clarity, uncluttered. The modern design of the piano becomes thick when you add dynamics. In contrast to this, for example, our pianos have on average a 27% reduced soundboard in the treble which results in less wood weight to set in motion. The result of this is an incredibly dynamic instrument, especially at pianissimo levels. You add power, yes without adding ‘thickness’. Composers like Liszt and Wagner were wanting pianos that would meld with voices and other instruments and not replace the orchestra. This has been Steingraeber’s mandate.

GB: Practically, then how do you accomplish this?

US: We believe that every part of the piano contributes to the overall tone of the instrument. All materials need to be thought of as sound sources. Not only the strings and soundboard but action parts, pedals and cabinet ~ all components must be viewed as tangible vibration energy. We call this Integral Thinking. Where many manufacturers use sound absorbing materials like pressboard (and MDF), we use only real wood (and honeycomb-like materials as used in aircraft construction) capable of resonating. Everything then resonates – even the grand lid and the keys.

GB: How else do you differentiate as a manufacturer?

US: Soundboard design is custom made for every piano. Every tree is different. There is no set pattern for soundboard resonance. While computer-controlled machines are precise, wood is neither uniform nor consistent. Hand crafting is the only way to accomplish this. For example, we test every soundboard with sand on the soundboard after it gets installed into the rim of the piano. By tapping on the bridge, it will reveal which parts are mobile and immobile. Hand scraping those areas, we create a membrane like that of a loudspeaker which can vibrate freely. The soundboard becomes very ‘live’ by doing so.

GB: I’ve heard people say many times that the piano never changes, but I’ve found that those invested in piano making are always reaching for new heights.

US: I agree. It’s always changing…always a work in progress.

GB: What are some of the innovations that Steingraeber has implemented?

US: We have re-introduced the historic Sordino pedal. This feature gives an incredible expressive soft sound by inserting a thin layer of felt between the hammers and the strings. During the devlopment of the piano, this used to be a standard feature on grand pianos in the early part of the 19th century with companies like Pleyel and Graf. This effectively accomplishes what Schubert writes in his music as “fp” marking.

We have also implemented the Mozart rail. Pianos in Mozart’s time had lower dip, meaning that the keys had shorter distance to travel downward. The Mozart rail reduces the key travel to 8mm – the appropriate distance during his time. The hammers on this Mozart rail also move closer to the strings. The overall effect is 2-fold: with closer hammers to the strings, the ability to play quieter is increased. The shorter dip in the keys also lends itself for quick playing as well.

GB: I tried this feature on the grand at the show here. It takes some getting used to because we’re so conditioned to 10 millimeters of dip. Reduction by 2 millimeters doesn’t sound like a lot but you notice it right away. And as you say, the fast, light playing is readily accessible.

US: We also have the lightest concert grand lids. They are up to 50% lighter than modern grand lids by implementing a honeycomb as the center core. This process is used in airplane manufacturing and not only is the grand lid light, but it also enhances the lid to vibrate as well.

We have introduced our own magnetic repetition option into our upright pianos making them feel like a grand piano. One of the drawbacks of standard uprights is the repetition of the key. Our uprights with magnetic repetitions only require a depth of 1-2 millimeters before the key can be repeated.

GB: I’ve also read that your innovations don’t stop there. In fact, you’ve done work with carbon fiber soundboards as well as adapting pianos for persons with disabilities. Incredible. Your production, you’re part of the German-made association Bundesverband Klavier (BVK).

US: Yes our pianos are over 90% manufactured in Germany. While the majority of our work happens in our facility in Bayreuth, our cast iron frames are made in Hanau or Nuremburg, Germany, bass strings partly from Heller in Eschelbronn. And of course we have a long standing relationship with Renner for German action parts as well as Wurzen felt makers, also located in Germany.

GB: And your personnel?

US: Our design team consists of 4 in house and 1 “advocatus diaboli” located in Switzerland. We have 6 master piano builders on staff as well as another 24 in production ~ 35 in total.

GB: I know you’re on the road and dealing with administration etc. but do you get to do hands-on work now and again?

US: Ahh I love voicing but I’m not very good at regulating. [he laughs]

GB: I’m sure being around this all of your life you hold your own in that realm. I appreciate you taking the time and giving us some insights into the manufacturing of Steingraeber Piano.

Steingraeber is a family run business established in 1820 celebrating 200 years in 2020! Udo and his wife Delia represent 6th generation and their children Alban and Fanny are already working in the company (7th generation). Not only are their pianos environmentally ethical, but their company workshops are emissions free and are paving the way with solar energy installed at the factory as well. Congratulations to Steingraeber on this milestone and again, many thanks to Udo for this insightful conversation.

MORE PIANO ARTICLES

You’ve been playing your piano for years now and the time has come to seriously consider downsizing the house and move into a condo. But what do you do with the piano? You love your piano and can’t imagine life without it and besides, you absolutely hate the idea of playing a digital keyboard. Many people don’t know that you can add digital functionality without compromising your existing piano. Yes, it is completely possible to ...

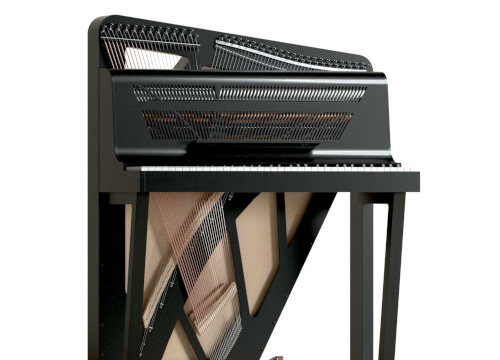

Many years ago, I remember seeing a piano in a museum similar to the one shown above (built in 1787 by Christian Gottlob Hubert. On display at Germanisches Nationalmuseum - Nuremberg, Germany). I have often wondered why acoustic portable pianos never really took off. Although we've seen more portable keyboard instruments like harpsichords, accordions or electronic keyboards, they operate completely different from a traditional piano in that they either pluck the strings, use air with ...

This was the first year since covid that the National Association of Music Merchants (NAMM) trade show was back to its regular January date and, in fact the first show where it felt back to normal. How was it? To answer that, I'm going quickly review the piano market over the last few years. Piano sales boomed during covid. Think about it - everyone was at home and with time on their hands, many turned ...

I’ve often wondered when the business model of piano buying would start to change. It seems like we feel comfortable purchasing everything from toothpaste to tires online and yet pianos are one thing that you still buy in a store. Well some of that is about to change. After speaking with Larry Caruso from Caruso Piano, they’re launching a brand of piano made specifically for online ordering. It’s called

Sonnova. I recently had the pleasure ...

The thought of buying a piano can be exciting but it can also be a bit intimidating or daunting, especially if you don’t know anything about them. But have no fear, because at Piano Price Point, we’ve compiled so much of the data and written articles to make your job easier. To narrow down the scope of buying a piano, you first need to decide what kind of piano you’re looking for. Ask yourself these ...

Money, apparently

does grow on trees or at least in ancient times it did. It's been recorded that rare tree sap was used as a form of payment for tax because it was deemed so valuable. This sap from the tree was harvested and refined into lacquer with incredible clarity and sheen. Many thousands of years ago, it was reserved for imperial palaces, religious temples and shrines. Early

examples have been dated to 7000BC. It ...