“World War II – July, 1944 ~ 71 years ago almost to the day, 85% of the Renner factory was destroyed. Wilhelm Megenhardt, then 70 years of age simply replied ‘We’ll just build it up again’. He continued working until 85 years of age after Renner had become a leading producer of piano parts. He was my grandfather.”

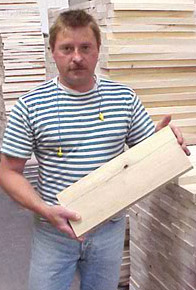

Glen Barkman: It was a delight and privilege to sit with Clemens von Arnim (pictured left) and ask him about his connection to Renner. I had no idea that it was his grandfather, Megenhardt who partnered with Renner in the early days of this business and eventually became sole owner.

Glen Barkman: It was a delight and privilege to sit with Clemens von Arnim (pictured left) and ask him about his connection to Renner. I had no idea that it was his grandfather, Megenhardt who partnered with Renner in the early days of this business and eventually became sole owner.

Established in 1882, Louis Renner opened a small workshop in Stuttgart. Operating with 25-40 workers, he built a successful business around making piano parts (also known as action parts). Twenty years later, as he began to struggle with his health, his son Oskar Renner assumed position as technical head of production. Shortly thereafter in 1906, in partnership with Wilhelm Megenhardt, they opened a modern factory manufacturing action parts as well as piano hammerheads.

Why is Renner important? Aren’t there other makers of action parts? The answer is yes, there are many makers of parts, it’s just that none of them have the reputation of Renner. Throughout the pages of Piano Price Point you’ll come across this phrase “Renner option available” or “Renner hammers”. When I’ve asked consumers, pianists and even aficionados about Renner, I usually hear a similar response: “I’ve heard of Renner but don’t really know what it’s all about.”

In short, Renner builds the finest action parts money can buy. The most prestigious, exotic piano makers in the world use Renner parts. Take a look at the chart below of piano companies that Renner supplies to.

In short, Renner builds the finest action parts money can buy. The most prestigious, exotic piano makers in the world use Renner parts. Take a look at the chart below of piano companies that Renner supplies to.  If you know some of the names on this list you’ll know that they produce the finest instruments in the world. And so why use parts from a company like Renner? Listen to the words of Clemens von Arnim to hear more:

If you know some of the names on this list you’ll know that they produce the finest instruments in the world. And so why use parts from a company like Renner? Listen to the words of Clemens von Arnim to hear more:

Demand

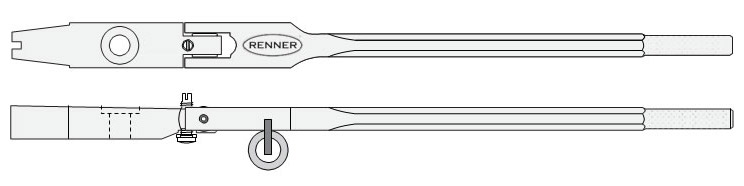

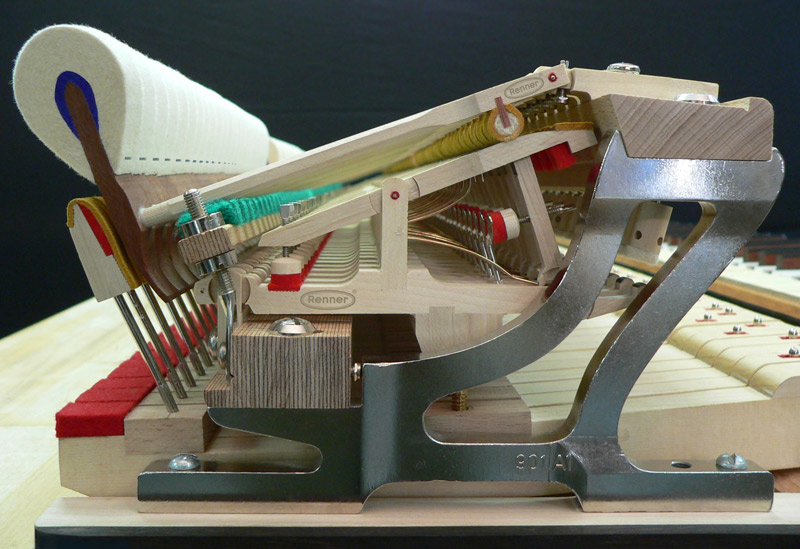

Clemins von Arnim: Our philosophy is based on 4 words: Quality, Reliability, Precision and Durability. How we accomplish that comes from the original mandate set out by Louis Renner himself. A standard grand action has more than 4000 parts. He set out to meet the demand for consistent quality. When you play a piano, all 88 notes need to respond precisely in the same manner and each of those keys has a minimum of 45 action parts. How does one manage to meet the stringent criteria for the highest level of quality? The answer is multi-faceted but let me start off by telling you a simple example that is decades old in the Renner factory about planing wood – one that set Renner apart. You see, to make piano parts, you must plane or cut wood to specific shapes and sizes. Cutting with the grain of wood is easy. Cutting across the grain at 90 degrees requires the correct tools. If the machinery is not extremely rigid, the edges of the cutting machine will ‘jitter’ against the wood and you will end up with course or substandard parts. In my grandfather’s era, at the Renner factory they over-built, over-constructed these planing machines to almost 2 ½ times the specifications so that cutting the smallest pieces would be accurate and smooth.

CvA: That original machine existed in our factory for decades. And it got replaced not because we had outgrown its usefulness, but rather automation in manufacturing prevailed. But it was this commitment to quality – to engineer and have machines that could produce the finest parts of the highest quality that set Renner apart more than a century ago.

GB:That story sounds like one where they call the inventor crazy until they see the end result. Tell me about your parts and how they are made.

CvA:

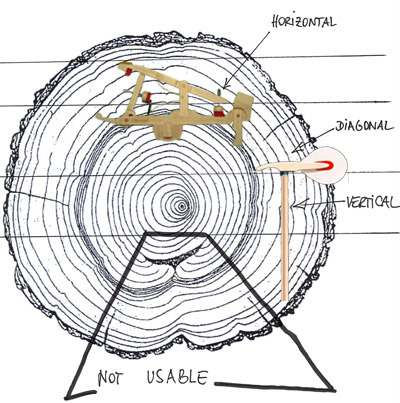

CvA: Our parts are made of hornbeam wood. Trees need to be cut between November and March when growth is slow and not so wet. Boards are then cut and air dried for one full year. This is very important because if you dry it too quickly, it has too much tension. It is then kiln dried until it reaches uniformity at around 8-9% humidity. After that, boards are sorted by our specialist for usage (see diagram). Vertical grain is used for hammer shanks while horizontal and diagonal grain wood is used for other action parts. In the end, 60% of our production lumber we deem as firewood and only use about 40% due to our stringent quality controls.”

DeliveryGB:

DeliveryGB: How has Renner managed to stay on top of the industry for so many years?

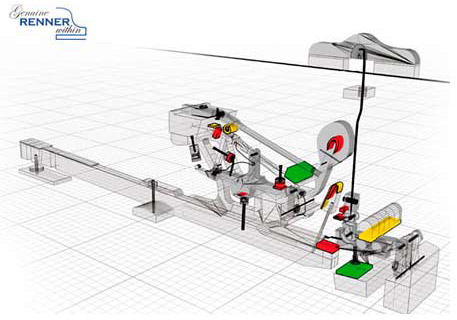

CvA: Aside from the commitment to quality, Renner has over 100 years of technical experience. There is a balance between modern automation and know-how when it comes to natural products. You cannot simply rely on machinery to have intuition regarding natural materials of wood and felt. And so 50% of our processes are automated and 50% involve hand-made personal touch. We have two facilities – one at Gärtringen (near Stuttgart) and one at Meuselwitz (near Leipzig). What has kept Renner going is that we can deliver and have met the demand without comprimise. Renner is the largest purely piano action manufacturer in the world. Over 3 million piano actions have left our production facilities.

GB: Somebody please do the math… conservatively 4,000 piano parts per action x 3 million actions… anyone? 12 BILLION parts. I think it’s safe to say that Renner can deliver.

[clearleft]

Diversity

CvA: In 1952, we expanded yet again to offer not only parts for new fabrication but also for repair and rebuilding. We manufacture over 1000 types of piano hammer heads. One of the reasons Renner continues to exist is the fact that we can supply not only volume but also make hammers with custom requirements. Clients tell us how firm the felt should be, how much felt is required around the wood and what sound they’re trying to achieve. We can troubleshoot and even offer suggestions to those wanting to customize action parts. Now, in the age of computer assisted design, the diversity is even greater. Over the years we have gained so much knowledge in working with wood and fibres of felt that we can control variances to very small percentages. Our tolerances at Renner are less than 1/10th of 1 millimetre which is sporty if you know what it’s like to work with natural products of wood and felt.

GB: This was one of those moments that made me smile .. “sporty” (I thought to myself) was the perfect word that describes the healthy pride in accomplishment and ownership but also denotes great satisfaction. 🙂

The Renner Advantage

CvA: Because of such tight tolerances in product manufacturing, our long standing knowledge base, combined with our hands-on technical team, we are capable of not only making beautifully crafted actions for today but also ones that will remain consistent for long periods of time. Our actions need little adjustment.

GB: If you’ve ever sat down at a piano with a Renner action, you’ll know that the touch and feel is superb. They play as smooth as silk and feel as rich as chocolate.

Many thanks to Clemens von Arnim. It was fantastic to meet face to face and to learn about Renner and the history of not only your family but the heritage that Renner has made. Renner has changed the world in creating music with the most prominent piano makers in history. The greatest concert pianists have played on piano actions created by Renner.

Renner has its own Academy for training purposes on piano actions. Below are some links to Renner around the world. Enjoy!

Renner Germany ~ Renner USA ~ Renner Academy

More Piano Articles

During the performance of Jacob Collier at the most recent NAMM show I was reminded that music makes us human, that beauty binds us together as a collective, and that the reason the music industry exists is to aid in the creation of art. I needed that reminder without which, the annual trade show featuring many of the great piano makers is just the sale of wares. I believe that people are feeling the uncertainty ...

I used to have a teacher who would frequently say, “For every single grade point PAST 80%, it takes as much effort as the FIRST 80.” I believe this statement to be true from experience. The first 80 is the easiest. Chipping away at every point past that is the challenge. The bulk of the work can bring a project into shape but it’s the pursuit of excellence, that’s where the challenge lies. Yamaha is ...

The value of a piano is obvious ~ it’s the music that you make with it. But often, families are going through life changes which involve a house move and unfortunately, the piano needs to be sold. They invariably ask the question, “What are we going to do about the piano?” This question comes up because, as you can imagine, they’re not easy to move. We don’t simply pack them away in a cardboard box ...

You’ve been playing your piano for years now and the time has come to seriously consider downsizing the house and move into a condo. But what do you do with the piano? You love your piano and can’t imagine life without it and besides, you absolutely hate the idea of playing a digital keyboard. Many people don’t know that you can add digital functionality without compromising your existing piano. Yes, it is completely possible to ...

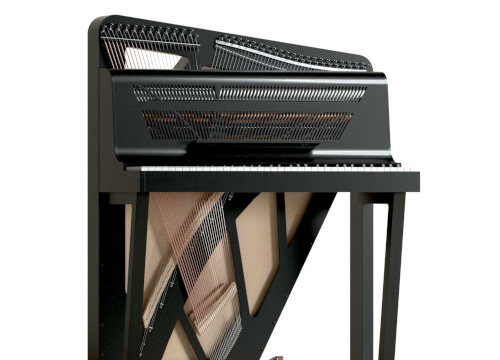

Many years ago, I remember seeing a piano in a museum similar to the one shown above (built in 1787 by Christian Gottlob Hubert. On display at Germanisches Nationalmuseum - Nuremberg, Germany). I have often wondered why acoustic portable pianos never really took off. Although we've seen more portable keyboard instruments like harpsichords, accordions or electronic keyboards, they operate completely different from a traditional piano in that they either pluck the strings, use air with ...

This was the first year since covid that the National Association of Music Merchants (NAMM) trade show was back to its regular January date and, in fact the first show where it felt back to normal. How was it? To answer that, I'm going quickly review the piano market over the last few years. Piano sales boomed during covid. Think about it - everyone was at home and with time on their hands, many turned ...