Today’s topic is piano dampers. When your finger depresses a key on the piano, the string vibrates allowing us to hear the wonderful tone of the piano. But what happens when we lift that same key? The key returns to its upright position and the tone stops resonating. Why? The piano mechanism called the dampers simply press felt blocks on the vibrating strings to terminate the singing tone.

Today’s topic is piano dampers. When your finger depresses a key on the piano, the string vibrates allowing us to hear the wonderful tone of the piano. But what happens when we lift that same key? The key returns to its upright position and the tone stops resonating. Why? The piano mechanism called the dampers simply press felt blocks on the vibrating strings to terminate the singing tone.

To understand a bit more about dampers, we brought in Marc Venet from world renowned felt maker Laoureux in France!

But before we delve into piano dampers, we need to take a brief look at the piano strings. On any modern piano there are usually 3 sets of strings: tri-chord, bi-chord and mono-chord. The prefixes of tri- bi- and mono- give away the fact that there are notes on the piano that contain 3, 2 and 1 string. This is significant because as we’ll soon hear, damping 3 strings at a time is very different than damping 1 string.  The largest strings on the piano are the bass strings. They are copper-wound strings and produce the lowest notes of the piano where you can actually see the vibration of the string. Conversly, as you move higher in the piano, the frequency of the waveform gets faster and we can’t see the vibration.

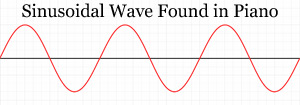

The largest strings on the piano are the bass strings. They are copper-wound strings and produce the lowest notes of the piano where you can actually see the vibration of the string. Conversly, as you move higher in the piano, the frequency of the waveform gets faster and we can’t see the vibration.  Piano strings can be called “sinusoidal” from where we get the root “sine” wave. The purpose of the damper then is to stop the wave and subsequently, the sound. The damping techniques and felt types are really different to mute different thicknesses of strings and their varying degrees of energy.

Piano strings can be called “sinusoidal” from where we get the root “sine” wave. The purpose of the damper then is to stop the wave and subsequently, the sound. The damping techniques and felt types are really different to mute different thicknesses of strings and their varying degrees of energy.

Without further adieu, and knowing a bit more of the background of dampers, let’s talk to Marc Venet from Laoureux.

Glen Barkman: The history of Laoureux, it’s been going a long time and is one of the largest piano felt makers in the world. Can you tell us a brief history of the company and how you got involved?

Marc Venet: Laoureux was founded in 1923 by Mr. Laoureux and after 3 generations of Laoureux’ leading the company until 1976, it wasn’t doing well financially. It was purchased by SCAPA group who bought the company in order to build a conglomerate in European felt business (Naish felts, Royal Georges felt, Laoureux, etc.)

My father was hired at this time in order to restore the profitability of the company Laoureux, which he succeeded to do above their expectations and quite possibly be the reason why Laoureux is now the only felt maker from this group that survived and producing today. The choice he made was to concentrate on high quality, hand made felts and avoid mass market felts like those found in the automotive industry, for example, which have bigger profits, yes but also involve big risks and large turnovers. It was a good choice. My father finally bought the company in 1988 and I joined the company in 1998.

GB: There are 3 types of strings and yet 4 types of dampers (mono,bi,tri and treble), can you tell us how each of those work?

GB: There are 3 types of strings and yet 4 types of dampers (mono,bi,tri and treble), can you tell us how each of those work?

MV: The shape and the types of dampers depend on the string they are supposed to damp.

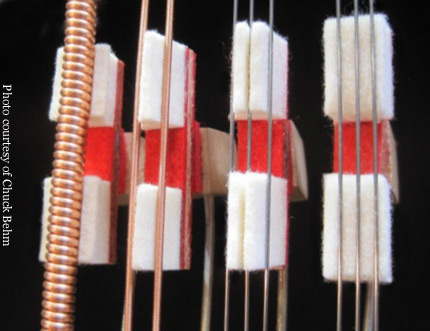

A – The “Mono” or “One string” looks like a square with a V shape inside in order to envelop the large string on bass section of the piano.

B – The “Bi” or the “Two strings” looks like a V shape in order to get inside the space between the two strings on the tenor section of the piano.

C – The “Tri” or “Tri strings” looks the same as the “two strings” wedge shape but contains a split in the middle to act as a double wedge. These are for the lowest plain wire strings.

D – the “Flat damper” looks like a cushion of low density felt and are used for the highest notes on the piano.

For all dampers the target is to damp the sound, that means that they are in charge of absorbing the vibrations of the strings. Those vibrations are in fact frequencies like sinusoid signals (pictured above). The bass notes have low frequencies which mean long and spaced sinusoidal waves, and on the contrary, the treble or high notes have high frequencies which mean shorts but repeated sinusoidal waves.

Of course, for playing the piano, it is interesting to have more or less the same time to dampen the sounds when you release the keys, wherever you play on the keyboard (bass, tenor, or treble) and yet the frequencies and subsequent energies are quite different. For achieving that, we use different dampers with different properties adapted for the frequency of the sound. On the treble section, frequencies increase drastically when you play more to the extreme treble section. So for this section, even if there are 3 strings for each note, we have to change the method of damping from the double wedge to the flat block dampers.

”

”

GB: Is there a certain density of felt that is ideal for piano dampers?

MV: Yes of course there are optimal densities for dampers. And there are also certain densities depending on the placement inside the piano (density for bass and for treble felt are different). Ideally the density should be as low as possible. You could find on the market bass dampers with densities from 0.23 up to 0.35 and for treble dampers ranging from 0.14 up to 0.25. Physically, density is weight over volume (D = W/V). For the felt manufacturer the challenge is to make low density felt because it has superior damping properties however it is much, much more difficult to produce. In order to be able to cut them with a high degree of precision (1/10 a millimetre) the felt should be perfectly consistent otherwise it is impossible to cut. The challenge is also for piano technicians, it is much easier to work with “hard” dampers when you do not have the correct know-how and experience. A soft felt is difficult to make on several levels: First, achieving the felting process for low density is very difficult, because if you are under the good “felting point” (felting being the intertwining of fibres), the middle of the felt will remain as only wool if it is not felted. And if you are over the optimal felting point you are too hard on the surfaces and soft in the center and thus, the felt is not consistent.

The job consists of making felt the same from top to bottom. This is not easy. It takes much more time, involving more hands-on processes and also involves a lot of waste. That is why it is more expensive than denser felt. Ironically, you pay more even if there is less wool inside because it is much softer but contains greater damping properties.

GB: In the cullinary world, it’s kind of like baking the cake right? Too hot and you burn the outside, too cold an oven and the center doesn’t get cooked. Interesting. Speaking of damping properties, what makes for great dampers? And can you take us through the manufacturing process a little?

MV: Wool is the first and natural technical fiber with a “form memory”. The felt pressed against the strings absorbs string vibration. If you leave the felt released, the impression will erase. This is what makes great dampers. The softer the felt, the better the form memory. Making great felt requires technical know-how but also great raw materials. Normally felt is graded by 2 criteria: the quality of the wool used and the density. We buy the wool taking into consideration the length of the fibers (told in millimetres), diameter of the fibers (told in microns), and ability to felt more or less (the curving of the fibers). Of course the thinner and the longest fibers are much more expensive than the shortest and the biggest fibers.

MV: Wool is the first and natural technical fiber with a “form memory”. The felt pressed against the strings absorbs string vibration. If you leave the felt released, the impression will erase. This is what makes great dampers. The softer the felt, the better the form memory. Making great felt requires technical know-how but also great raw materials. Normally felt is graded by 2 criteria: the quality of the wool used and the density. We buy the wool taking into consideration the length of the fibers (told in millimetres), diameter of the fibers (told in microns), and ability to felt more or less (the curving of the fibers). Of course the thinner and the longest fibers are much more expensive than the shortest and the biggest fibers.

Process :

A – Wool opening and Blending: we make a blend of wool with different single lots in order to have something always the same. With blended wine for example, you assemble different qualities with more or less the same proportions to create consistency. If we were using only one type of wool for each production, we would have different results from one production run to another and so good blending allows consistency in production.

B – Carding: the blend goes into the carding lines in order to create wool layers. With our machines we can adjust the weight by square meters of the layers, and also the fiber direction (crossed or not).

C – Composition: It is a hand made process consisting of assembling and cutting several wool layers depending on the final result we want to achieve. In short, we know the final dimension and density we want. We will use the right weight of wool at the right dimension taking in consideration the shrinking coefficient we will apply.

D – Felting: The transformation between wool to textile. It is a natural process (no chemicals involved) where the fibers are matted together via friction.

E – Fulling: Once we transformed the wool layers to felt, we have to shrink it to it’s final dimension in order to give it it’s right density. This is again a hand-made process, one piece at a time. Dimensions of the felt should be controlled because we need to keep consistency in the shrinking. The right density is obtained when the felt is at the right dimension, not before, not after.

F – Drying. The previous process of felting and fulling require moisture and so the felt must be dried.

” width=”140″ height=”185″ style=”margin: 20px 10px 0px 0px;” />

” width=”140″ height=”185″ style=”margin: 20px 10px 0px 0px;” />

G – Pressing: Here we calibrate the thickness of the felt, for example 10.2 mm thick. We use hot presses to achieve this.

H – Finishing: Depending the product we make it goes to the dedicated workshop in order to be cut or assembled to its finished purpose.

GB: Aside from piano felt, what other applications do you make felt for?

MV: There are many many different applications for felt. Felt is used for its natural properties of absorbing, transferring and sealing. Some industrial fields using felts: writing instruments, railway, automotive, nuclear, tools, bakery, design and of course, piano making.

Glen Barkman: Wow that was a fantastic glimpse inside the world of felt making by Laoureux. They are located in Normandy, France and operate in 7,000 m2 facility (about 75,000 ft2 factory). A special thanks to Marc for his expertise and continued dedication in providing the world with quality felt.

More Piano Articles

During the performance of Jacob Collier at the most recent NAMM show I was reminded that music makes us human, that beauty binds us together as a collective, and that the reason the music industry exists is to aid in the creation of art. I needed that reminder without which, the annual trade show featuring many of the great piano makers is just the sale of wares. I believe that people are feeling the uncertainty ...

I used to have a teacher who would frequently say, “For every single grade point PAST 80%, it takes as much effort as the FIRST 80.” I believe this statement to be true from experience. The first 80 is the easiest. Chipping away at every point past that is the challenge. The bulk of the work can bring a project into shape but it’s the pursuit of excellence, that’s where the challenge lies. Yamaha is ...

The value of a piano is obvious ~ it’s the music that you make with it. But often, families are going through life changes which involve a house move and unfortunately, the piano needs to be sold. They invariably ask the question, “What are we going to do about the piano?” This question comes up because, as you can imagine, they’re not easy to move. We don’t simply pack them away in a cardboard box ...

You’ve been playing your piano for years now and the time has come to seriously consider downsizing the house and move into a condo. But what do you do with the piano? You love your piano and can’t imagine life without it and besides, you absolutely hate the idea of playing a digital keyboard. Many people don’t know that you can add digital functionality without compromising your existing piano. Yes, it is completely possible to ...

Many years ago, I remember seeing a piano in a museum similar to the one shown above (built in 1787 by Christian Gottlob Hubert. On display at Germanisches Nationalmuseum - Nuremberg, Germany). I have often wondered why acoustic portable pianos never really took off. Although we've seen more portable keyboard instruments like harpsichords, accordions or electronic keyboards, they operate completely different from a traditional piano in that they either pluck the strings, use air with ...

This was the first year since covid that the National Association of Music Merchants (NAMM) trade show was back to its regular January date and, in fact the first show where it felt back to normal. How was it? To answer that, I'm going quickly review the piano market over the last few years. Piano sales boomed during covid. Think about it - everyone was at home and with time on their hands, many turned ...